Aluminum chain lever block

Couldn't load pickup availability

Use this text to encourage communication or promote sharing on social networks.

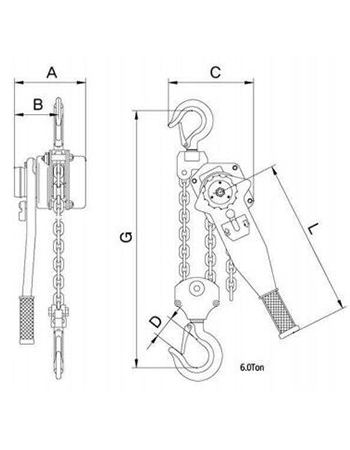

Aluminum chain lever block

Description

Aluminum chain lever block

Features:

Aluminum chain lever block in detail

Aluminum chain lever block, also known as chain tensioner or lever chain tensioner, the main body is made of high-strength magnesium aluminum alloy, the chain is made of high-strength special alloy steel, and the chain hoist is imported from Japan. Made of alloy. The aluminum alloy chain hoist has a beautiful appearance, which greatly reduces the weight of the lever hoist and is easy to carry. The aluminum alloy chain lever hoist is mainly used for lifting and traction. The aluminum alloy chain lever hoist has the same excellent performance and reliable operability as other lever hoists, and can still be used without power.

Advantages of aluminum chain lever block:

- The high-strength, high-plasticity aluminum alloy box greatly improves the strength of the product while maintaining its light weight.

- Two-stage speed change and short handle make operation more labor-saving.

- The handle that can be rotated 360^ provides a variety of operation modes in a limited space.

- The sprocket mechanism that can rotate freely in the neutral gear ensures that the chain can pass quickly and lightly.

- The fully enclosed, automatically adjustable brake system can effectively eliminate shocks while keeping the brakes clean and dry, making work safer and more reliable. The position of heavy objects can be controlled by micro motion.

Application fields of aluminum chain lever block:

The products are used in machinery and equipment for infrastructure construction projects such as electric power, shipbuilding, automobile manufacturing, construction, highways, bridges, metallurgy, mines, slope tunnels, and shaft treatment and protection.

Technical Data

| Capacity (T) |

Standard lift height (m) |

Test load (kn) |

Rated forward hand power (n) |

Dia.of laod chain (mm) |

No. of load chain | min.distance between two hooks (mm) |

Net weight (kg) |

main dimension(mm) | Added weight per added meter(kg) | ||||||

| A | B | C | D | E | (I) | ||||||||||

| 3 | 1.5 | 36.8 | 340 | 7 | 1 | 420 | 9.5 | 180 | 106 | 132 | 450 | 31 | 45 | 1.05 | |

| 6 | Pin type | 1.5 | 73.5 | 360 | 7 | 2 | 500 | 16.5 | 180 | 106 | 155 | 450 | 45 | 24 | 2.18 |

| Hook type | 1.5 | 73.5 | 360 | 7 | 2 | 535 | 16.3 | 180 | 106 | 175 | 450 | 39 | 55 | 2.18 | |

Features