Explosion Proof Copper Material Electric chain hoist

Couldn't load pickup availability

Use this text to encourage communication or promote sharing on social networks.

Explosion Proof Copper Material Electric chain hoist

Description

Aluminum bronze and beryllium bronze are used as the blank of explosion-proof copper chain electric hoist. The shell of explosion-proof copper chain electric hoist is made of H62 copper alloy. Its rotating gear is heat treated at high temperature to achieve high wear resistance. In the operation, the products will not produce mechanical sparks due to mutual friction and impact, and the gas will not be ignited in flammable and explosive places, so as to effectively prevent fire accidents.

Technical Data

| Capacity (kg) |

Lifting speed (m/min) |

Lifting heigh (m) |

Motor Type | Power (w) |

Motor speed (r/min) |

Voltage (v) |

Size (mm) |

Weight (kg) |

||||

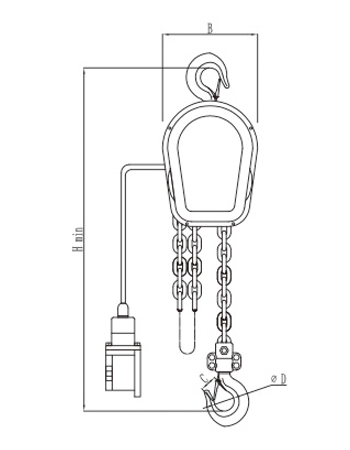

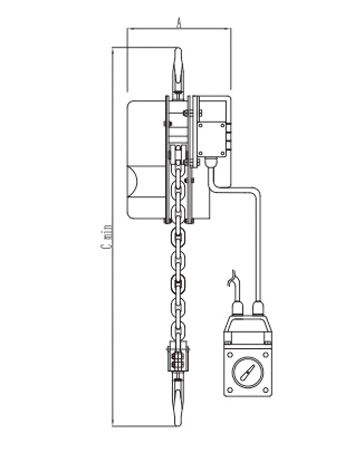

| A | B | Hmin | C | D | 3m | |||||||

| 1000 | 2.25 | 3-9 | YHPE500-4 | 500 | 1380 | 380 | 280 | 275 | 520 | 580 | 43 | 40 |

| 2000 | 1.85 | 3-9 | YHPE500-4 | 500 | 1380 | 380 | 280 | 275 | 600 | 630 | 50 | 43 |

| 3000 | 1.1 | 3-6 | YHPE750-4 | 750 | 1380 | 380 | 280 | 275 | 680 | 780 | 63 | 50 |

| 5000 | 0.9 | 3-6 | YHPE750-4 | 750 | 1380 | 380 | 280 | 275 | 710 | 820 | 65 | 70 |

| 7500 | 0.6 | 6-9 | YHPE750-4 | 750 | 1380 | 380 | 280 | 340 | 850 | 970 | 72 | 72 |

| 10000 | 0.45 | 6-9 | YHPE750-4 | 750 | 1380 | 380 | 280 | 358 | 900 | 1050 | 77 | 107 |

Features

Working principle

Adopting star speed reducer and disc motor, it runs smoothly, brakes accurately and safely, and is suitable for all kinds of clean, flammable and explosive working space.

Explosion proof copper chain electric hoist is a kind of easy to use, easy to carry electric lifting machinery, light weight, easy to carry, beautiful appearance, small size, durable.

The explosion-proof copper chain electric hoist can be used together with the explosion-proof electric monorail trolley to form an electric lifting and transportation trolley. The explosion-proof copper chain electric hoist can be widely used in petroleum, petrochemical, oil stations, oil depots, gas production, chemical, military, electric power, mining, electronics, railway, and other potential fire and explosion hazardous environments. In the operation, the products will rub and collide with each other, resulting in machine failure It can effectively prevent fire accidents and ensure national property and personal safety. It is also an indispensable special tool for machinery manufacturing and maintenance.